You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building the ultimate sleeper saw.... 46cc Craftsman into a ported 72cc

- Thread starter Arrowhead

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Streblerm

Addicted to ArboristSite

That is freaking awesome. And I thought my 60cc poulan was a sleeper. The AM 038 parts are even cheaper than the OEM 60cc poulan top end. I may have to consider a project like this. I'm amazed that it went together as (relatively) easily as it did. Great work.

This would be a great upgrade for the 330/380/3450/3750 series of saws. They are very similar. I may be wrong but I was under the impression that the crankcase was a bit wider. It may reduce some of the clearancing that needed to be done on the cylinder and flywheel.

Freaking Awesome!!!:msp_thumbsup::msp_thumbsup::msp_thumbsup:

This would be a great upgrade for the 330/380/3450/3750 series of saws. They are very similar. I may be wrong but I was under the impression that the crankcase was a bit wider. It may reduce some of the clearancing that needed to be done on the cylinder and flywheel.

Freaking Awesome!!!:msp_thumbsup::msp_thumbsup::msp_thumbsup:

This is much more interesting than the earthquake thread :hmm3grin2orange:

I got me a craftsman like that. Cool bananas.

Are you going to put an 056 Magnum top end on yours?

outdoorlivin247

Addicted to ArboristSite

Hmmmm, must be sleeping in this morning...:msp_sleep:

8433jeff

Aftermarket connoisseur

Are you going to put an 056 Magnum top end on yours?

Love to see that with the dual port exhaust towards the back.

Ed, I would have waited for a buildoff, at least a race of some sort. Wheres the guy that said Poulans were nothing but complete junk? I don't think a MS250 could absorb that much extra power. I have doubts that an 026 would hold up.

8433jeff

Aftermarket connoisseur

Hmmmm, must be sleeping in this morning...:msp_sleep:

So you do still walk this earth.

Mastermind

Work Saw Specialist

watsonr

Addicted to ArboristSite

- Joined

- Jan 3, 2010

- Messages

- 7,088

- Reaction score

- 2,130

Maybe you should sell the bushing so everybody can do this mod... flywheel too?

8433jeff

Aftermarket connoisseur

I've been fighting with the stomach flu all week.... I think it won this morning. :msp_sad:

Get well soon, Arrowhead.:msp_smile:

I am very impressed with the work so far and your vision for doing such a Mod. It shows your over all knowlege of many different brands of saws and your skills as a mechanic and machinist. I like it.

I tried to rep you but I have to spread some around.

Thank you, but I'm not a machinist, just a beginner trying to learn. My friend is the experienced machinist, he was coaching me.

Nice work, Ed! That Craftsman looks familiar. :msp_wink:

Yep.

Do your bushings have a lip to contain the piston pin? Then the circlips hold the bushing?

Tom, the bushings has a very slight taper on the end. They get installed from the center of the piston with the taper towards the rod. They basically lock into place.

thomas1

sodium pentothal

- Joined

- May 2, 2010

- Messages

- 3,651

- Reaction score

- 1,092

Thank you, but I'm not a machinist, just a beginner trying to learn. My friend is the experienced machinist, he was coaching me.

Yep.

Tom, the bushings has a very slight taper on the end. They get installed from the center of the piston with the taper towards the rod. They basically lock into place.

If you need another Craftsman, I think I saw one in the pile at one of my local dealers.

So, what numbers did ya end up with? Cutting the skirt take your intake way up?

Also, What was the stroke difference between em?

The timing numbers were EX. 106

TR. 130

IN. 77

I may go back and raise the transfers some.

I adjusted them to ... EX. 100

TR. 130

IN. 80

The stroke is the same on both. There was plenty of skirt. That's how I adjusted the number, by trimming the skirt instead of dropping the port.

Hedgerow

HACK

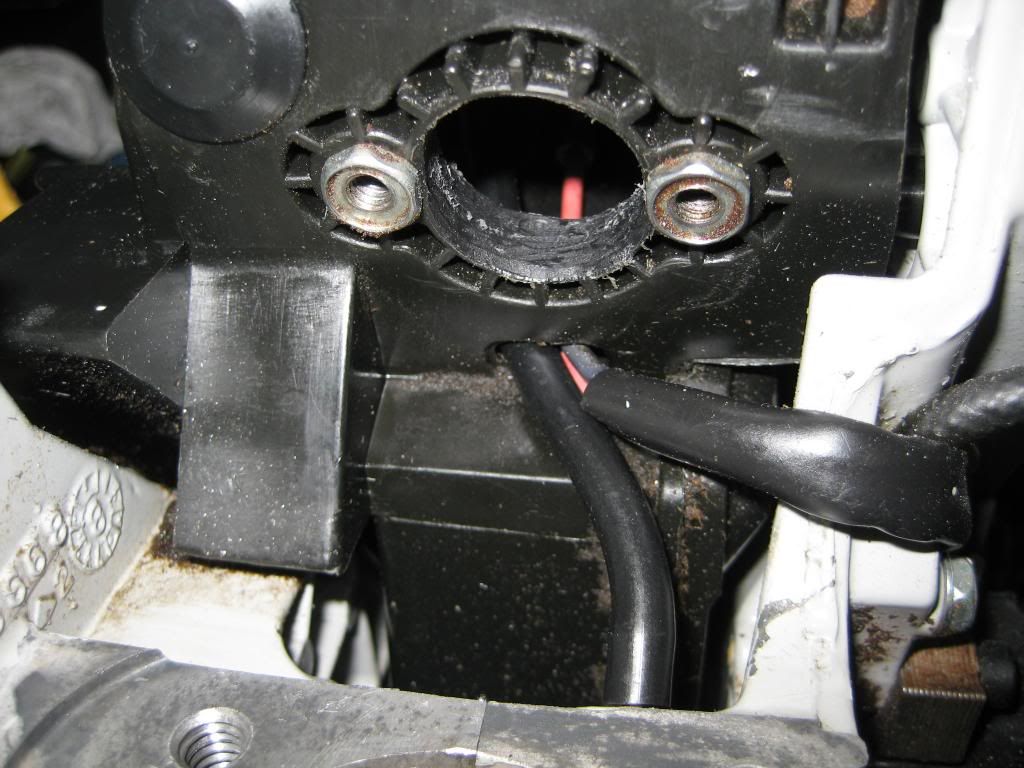

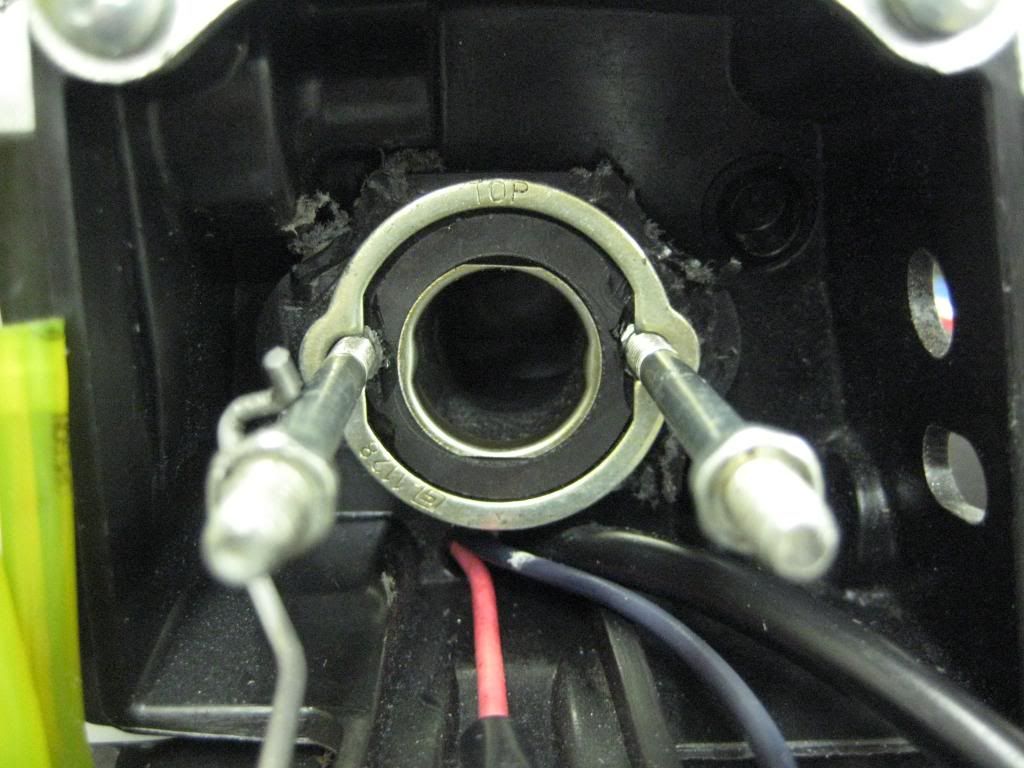

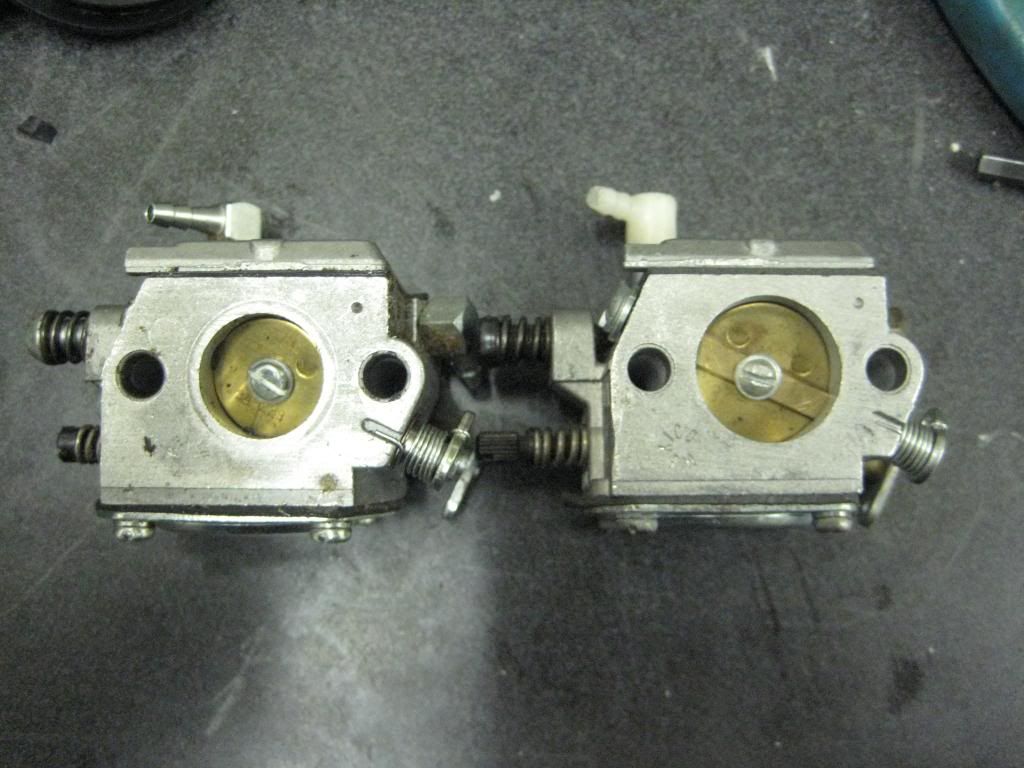

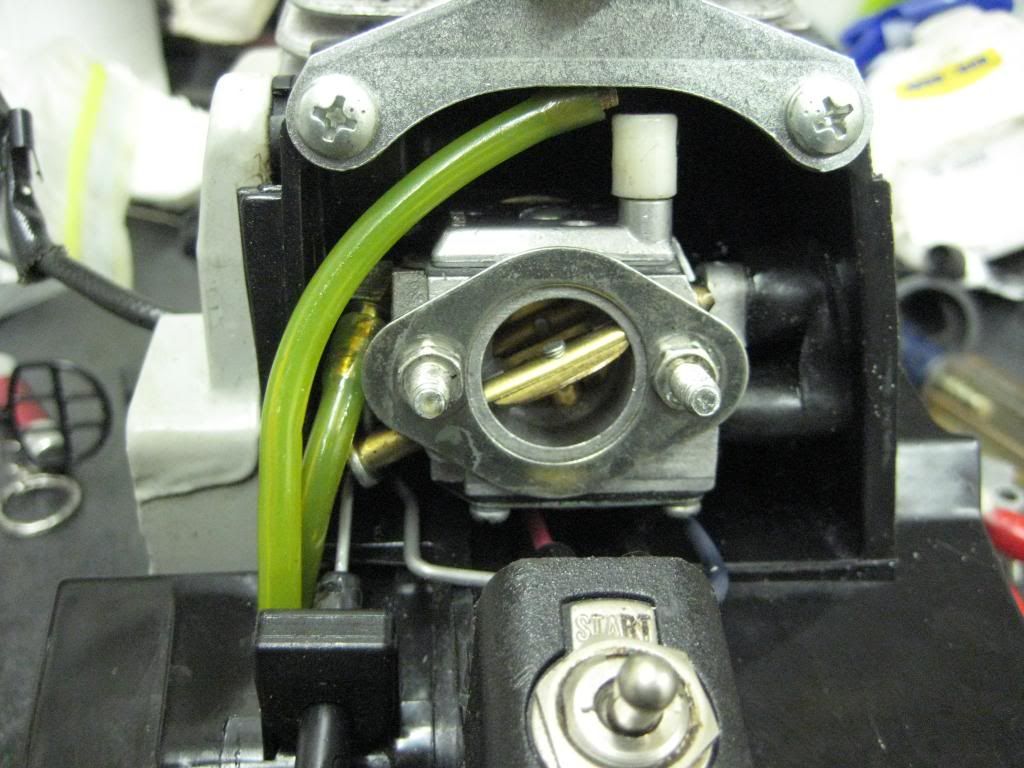

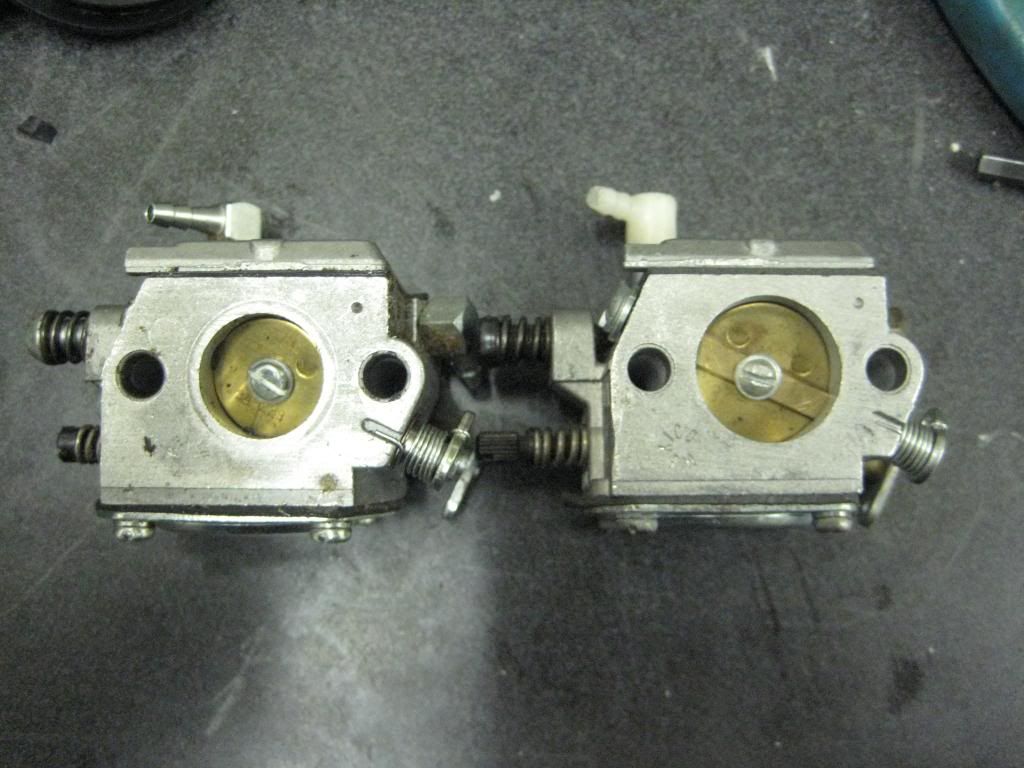

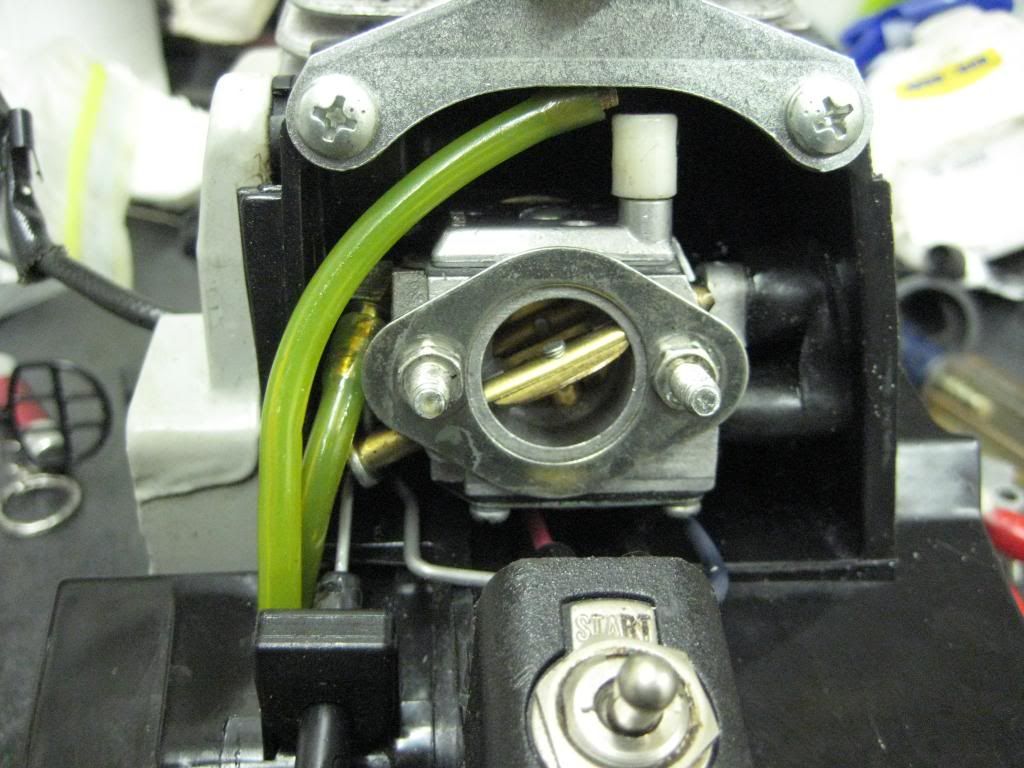

ModifiedMark was nice enough to tell me the larger carb that is a direct bolt on. It's an HDA ?? ( I forget). He did tell me that series carb had some issues. I thought I bought an nos older one (before the problems). But I'm thinking not. The low screw is probably 2.5 full turns out. :msp_mellow:

It 4 strokes fine, but something don't seem right with the carb. Maybe Mark will chime in and explain the issues. New carb is on the right.

It 4 strokes fine, but something don't seem right with the carb. Maybe Mark will chime in and explain the issues. New carb is on the right.

Last edited:

Similar threads

- Replies

- 110

- Views

- 12K

- Replies

- 0

- Views

- 550

- Replies

- 7

- Views

- 411

- Replies

- 155

- Views

- 6K