I sat and stared at this P&C for a good long while trying to decide what I wanted to do with it. In the end, I basically treated it like any other saw. The only thing the strato really does is add that extra puff of fresh air to help push out the exhaust. I also believe I can explain why WOT tuning RPMs are not that high, and why it can't be pushed as far/hard as a 361.

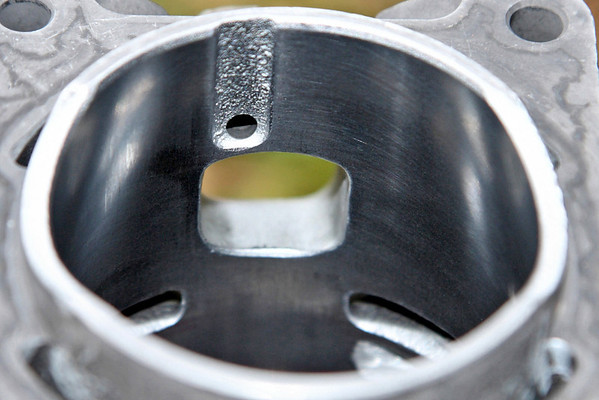

Look at the intake port. It's only about half the width of a normal intake. It's limited by the pockets in the piston that carry the strato charge. All fuel comes through that one small intake port. So it only stands to reason that it can't flow what a traditionally ported engine can. I was able to widen it a little, but not much. I did lower it 4°, but it would need a lot more width to do more. The intake and carb are matched accordingly. So those are bottle necks as well.

Here are the beginning and final port timing numbers.

Exhaust 103° - 100°

Transfers 131° - 124°

Intake 73° - 77°

As you can see, I raised the transfers a lot. I also widened the rear ones. Transfer flow is needed to maintain RPMs in the cut, so they had to come up considerably.

The exhaust was a little low stock, but I don't like to raise it much. I build for torque and compression is your friend.

Now for the pics.

Here's the tiny intake. You can see where the edge of the skirt rides. I went as wide as I could.

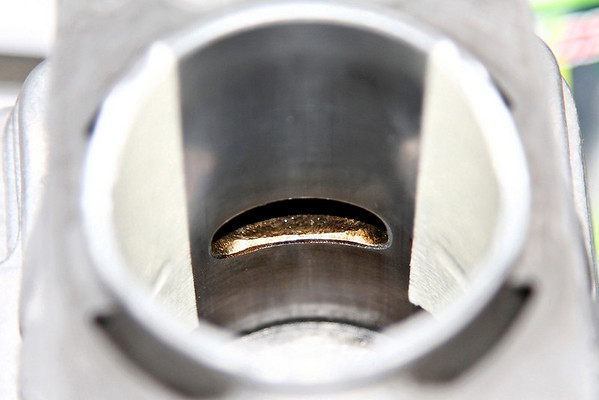

I widened the exhaust a TON. I went a full 70%, as measured along the curve. I wouldn't doubt that I widened it at least 3/8"!

I widen it at the flange as well and taper it all the way in.

I raised the tranfers a lot as well. They were really low to begin with at 131°.

On the strato ports, I only slightly widened them. I did very little to them.

Thought for sure I won the Million dollars!

Thought for sure I won the Million dollars! click on the link i posted

click on the link i posted