Bruce Hopf

ArboristSite Guru

Before you started tearing down your saw, did you happen to check and see how the spark was? Did you happen to see weather or not if the saw would at least offer to start prior to disassembling the saw? Or are you planning to fix up this Chain Saw, for display?Okay You asked for it!

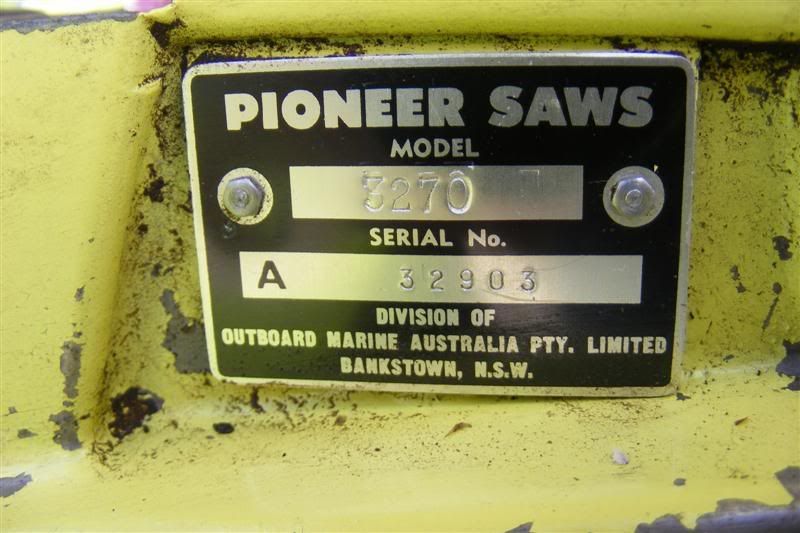

Okay so my plan is to strip this old P20 down, learn all about the different components and if it looks good inside put it back together and see if it will run.This is the saw my neighbor found at the steel dump, there is a little piece of broken magnesium near the end of the handle just cosmetic so I will use this as my first work piece.I would rather start with this one learn the in's and out on it.So the flywheel is off,and I saved the key it is in perfect shape.I have taken out all the screws around the case out.Taken the screws out that are around the points condenser area.The bar chain and cover for the sprocket are off.Two big screws from the plastic carburetor base are out,but the carburetor will not come out of it's little area because the choke knob is holding it in there and maybe something else besides the fuel line.How does that choke knob come off, it's bent around the linkage of the choke.The black plastic choke knob has a wire that comes out of it and that is attached to the for mentioned linkage.After I figure out how to take the carb out will the cylinder come off once the cylinder base bolts are out?It seems pretty tight on there.When can I start to try and split the case in half.Will I need these other pullers to finish the job?Sorry for the jumping around on this, many thoughts are bouncing around in my head, just want to try and accomplish this with out breaking any thing,or twisting things when they should not be twisted.

Thanks For Listening well reading

When I get a used saw in, from other Small Engine Repair Shops, that handle Chain Saws. I first determine weather or not it has good spark. If not I try to put in an Ignition Module in place of the points and condenser. After this, I check to see how good the spark is.If I get good spark, I put some Gas/Mix into the Carburetor Throat, to determine if the saw will at least offer to run, or run, prior to putting in too much time and effort into the saw, and decide to make it a working saw, or parts saw. Bruce.