You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Started my splitter build

- Thread starter Eric K

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Eric K

ArboristSite Operative

Mudstopper I am using a dump from splitez splitters. I am up sizing all lines, suction , and return. No 90's should keep the heat down plus having 35 gallons of hydraulic will help hope I'm on the right track.

nathon918

Addicted to ArboristSite

yup thats what i wanted too, i didnt want to have to deal with stablizer legs and the like... i think it would be fine as long as you dont fly down rough roads.I was more concerned about having a solid platform when using the log lift. Didn't want it bouncing.

Mudstopper I am using a dump from splitez splitters. I am up sizing all lines, suction , and return. No 90's should keep the heat down plus having 35 gallons of hydraulic will help hope I'm on the right track.

You get your pump from splitez also, It seems they have some pretty good prices.

I used 3/4hoses all the way thru on my machine. I dont have a autocycle valve, just a regular splitter valve. My tank is on the small size, 15gal cap. Tank size will help a bunch with cooling, and the dump valve will help with speed. Yea, I think your on the right track

Oliver1655

Addicted to ArboristSite

Eric, I used a 7,000 lb mobile home axle, springs with 8 ply tires. There is a 5' spacing between the springs. The tongue goes under the out-feed tables. I do not have any other stabilizers & it is stable while the log lift is in use. I also use the log lift for a staging table so it has quite a bit of weight on it. This is a normal load in the photo.

Eric K

ArboristSite Operative

Looks real good Oliver. Down the road if I have problems with my hubs I will change to a torsion axle. I think the hubs I used will hold up though. If you look at post #88 in the second pic the hub fits into that counter bore. It goes in there .550 and it has a two thousandths clearance. So it is supporting the weight and the bolts basically hold it in place.

Oliver1655

Addicted to ArboristSite

I agree you shouldn't have any problems.

This info was to help others who are considering building a splitter. You are going to have an amazing splitter when you are done!

This info was to help others who are considering building a splitter. You are going to have an amazing splitter when you are done!

Eric K

ArboristSite Operative

Thanks Oliver !!! There are so many ways to do things and having never built one it is easy to start thinking oh I should have I done this or that. Lol !!!!!! My one major mess up was back in post # 31 when I had do some rework. The other thing is I need to slow down a little I get to hurrying. I am at 81hours now in this build. I plan during the week and jam on Saturday and part of Sunday. Thanks to all who have commented and given advice and shared their successes and failures. Sure does help a bunch.

nathon918

Addicted to ArboristSite

the issue with that type of hub is not the mount to the axle, its the bearings, usually if it goes bad, and you dont catch it in time, the bearings fall apart and the spindle can fall right out of the housing, and thats even more of an issue if their overloaded. those are one of the worst things to happen to cars/trucks.Looks real good Oliver. Down the road if I have problems with my hubs I will change to a torsion axle. I think the hubs I used will hold up though. If you look at post #88 in the second pic the hub fits into that counter bore. It goes in there .550 and it has a two thousandths clearance. So it is supporting the weight and the bolts basically hold it in place.

they are almost always rusted to the knuckle or axle, and have to be pressed, or beaten out, if theyre loose, they need to be replaced, they cant be adjusted, i hate the damn things. tapered roller bearing spindles and hubs are soo much stronger and last alot longer, and cheap and easy to fix.

i have em on the front axle of my dodge 3500 diesel, as soon as they go, its getting free spin hubs, with manual lock in's, and ill never need to replace the bearings again...

jthornton

ArboristSite Guru

I used a Dodge K car rear axle with trailer springs. I have stabilizer jacks for the rear when splitting so it doesn't wobble.

JT

JT

Mudstopper I am using a dump from splitez splitters. I am up sizing all lines, suction , and return. No 90's should keep the heat down plus having 35 gallons of hydraulic will help hope I'm on the right track.

I have basically the exact set up you are planning on and have no heat problems. Using 3/4 lines, dump valve and long sweep 90's when it has to be done. Plan your layout to avoid as many as possible on the pressure side of things. James at Splitez is the best!

timbrjackrussel

ArboristSite Guru

Just let some air out of the tires to smooth out the bumps. I have a heavy splitter with no springs and run about 10-15 PSI.I only need to tow this unit 10 miles round trip most of the time. If the hubs don't hold up I will put a torsion axle under it.

jthornton

ArboristSite Guru

I'm not sure I just unbolted the spindle from the axle when I shortened it. I do remember pressing the brake drums off as I didn't need them.Jt does that K car axle have spindles or a do they use sealed wheel bearings

JT

The K car axles have spindles with replaceable bearings.

Eric K

ArboristSite Operative

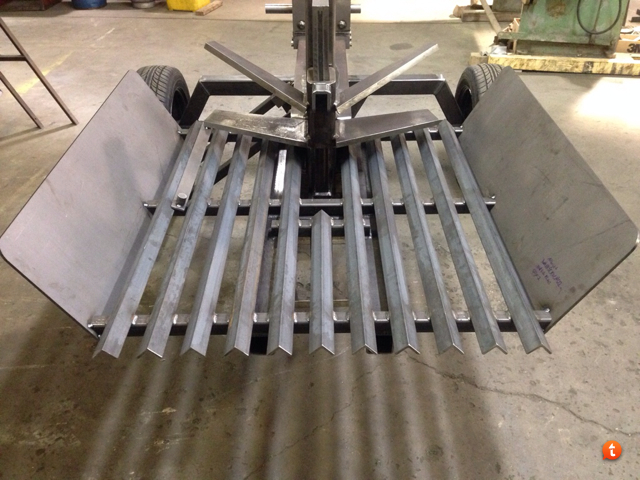

Side plates installed.

View from the side.

Log lift and cylinder mounts tacked in place. I am going to put some plate on it. Just waiting for the cylinder to make sure no changes are needed.

Another view of the lift.

Similar threads

- Replies

- 17

- Views

- 2K

- Replies

- 11

- Views

- 2K

- Replies

- 43

- Views

- 2K

- Replies

- 93

- Views

- 4K

- Replies

- 78

- Views

- 6K