Gypo Logger

Timber Baron

Good day fellas,

Lately I have been getting alot of PM's and emails regarding the 044 I built which was my first saw that I ever modified.

It did well at Jokers and Eric's GTG so to benefit those who have asked I took the saw apart to take pictures.

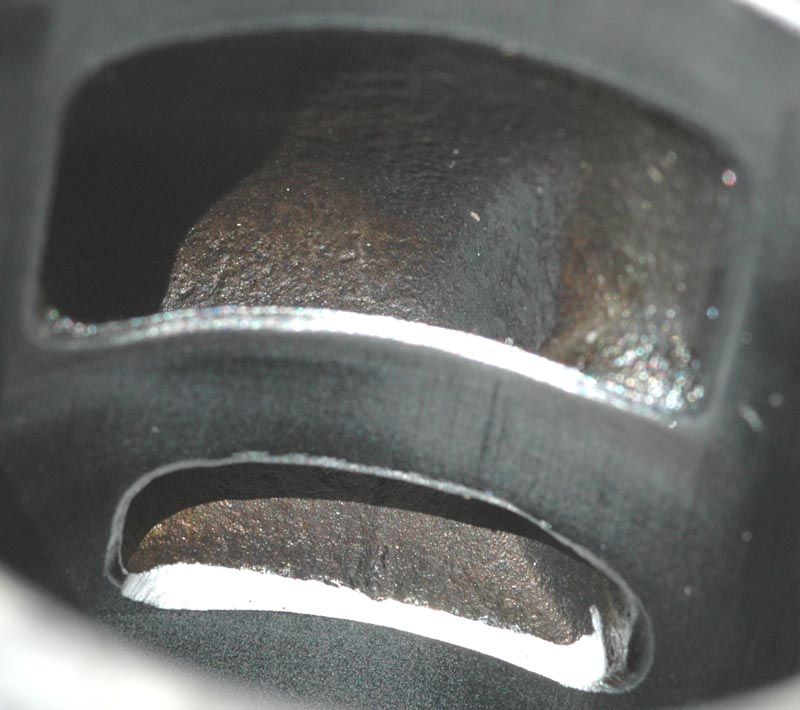

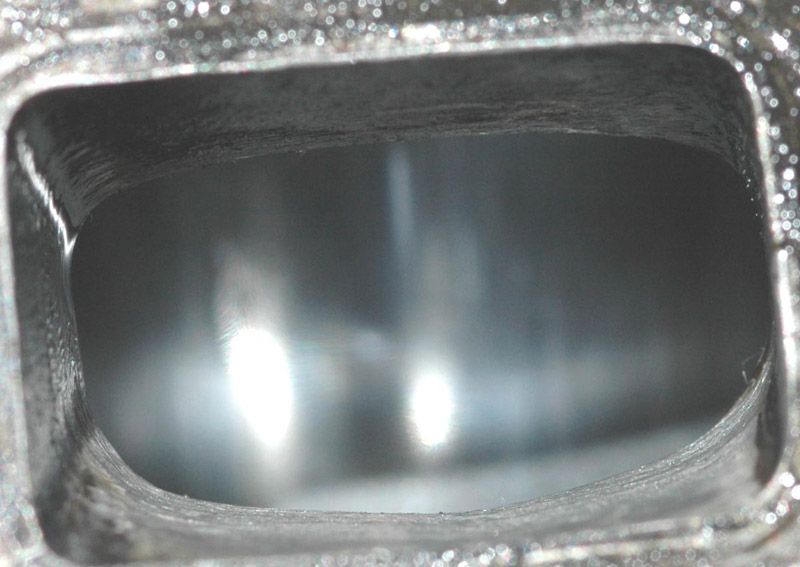

Basicly the intake was lowered by 1mm and the exhaust was raised by 1mm.

I also angled up the transfers approx 1mm. I didn't have a 90 degree angle tool to get in there, but it got the job done.

It may look rough, but hey, it was my first saw.

The only thing I changed today, was I put a slightly better piston in it.

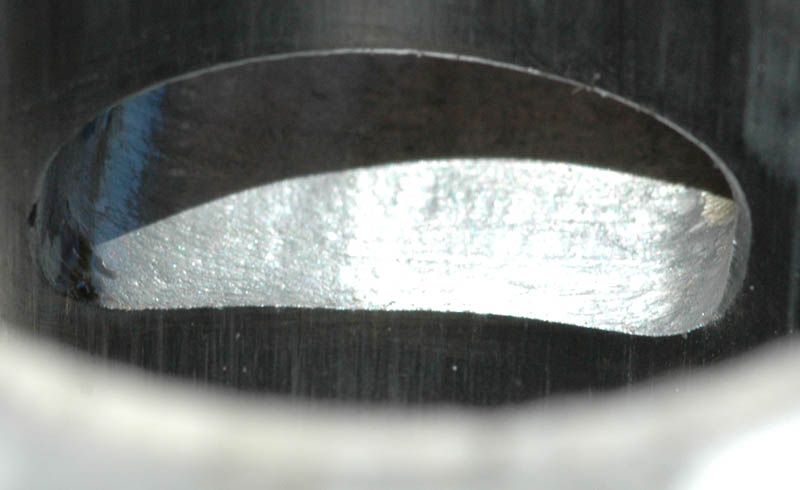

Anyway, here's some pictures. This first picture is the piston that I have been running since I built the saw. I just cleaned it up and put in new rings.

I know it looks rough, but it works.

John

Lately I have been getting alot of PM's and emails regarding the 044 I built which was my first saw that I ever modified.

It did well at Jokers and Eric's GTG so to benefit those who have asked I took the saw apart to take pictures.

Basicly the intake was lowered by 1mm and the exhaust was raised by 1mm.

I also angled up the transfers approx 1mm. I didn't have a 90 degree angle tool to get in there, but it got the job done.

It may look rough, but hey, it was my first saw.

The only thing I changed today, was I put a slightly better piston in it.

Anyway, here's some pictures. This first picture is the piston that I have been running since I built the saw. I just cleaned it up and put in new rings.

I know it looks rough, but it works.

John