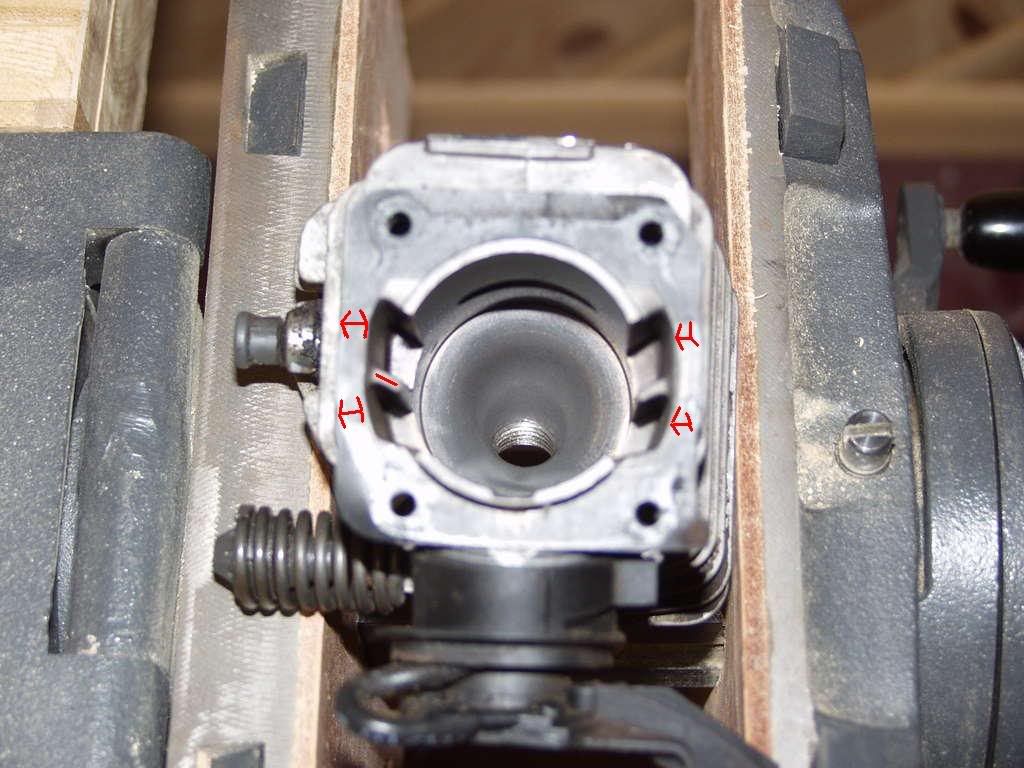

I'm not the best picture drawer so bear with me. In this picture you can see the basic idea of the engine: the green parts is where the fuel and air is. I like to pack as much fuel and air in this area as i can so improving flow into here is a big improvement. I see a lot of weed wackers and some chainsaws that could really improve in the intake area as well as exhaust. I notice a lot of small engines that have a very short intake duration (meaning how long the port window is open) and short exhaust duration. If you lower the intake port a little(dont go overboard here as you need some closed time).The closed time is the time its pushing the fuel air mixture into the combustion chamber. If you didnt have a closed time it would spray fuel out the carb and not into the transfer ports and into the combustion chamber. When you get into duration and such the main thing is to watch the video at the very top or watch basic 2 stroke operation and think in your head of the rhythm of the engine, makes me think of those old hit and miss engines. Take that rhythm and go look at your chainsaw engine and crank it around a few times by hand and watch how the ports open and close. You should see a rhythm now as you're watching the ports open and close realtive to how the piston travels. The faster the ports open and close the more rpm you get. The distance from the intake to the exhaust is somewhat like intake exhaust intake exhaust intake exhaust intake exhaust. If you have some distance between the ports you will get a rhythm like intake space exhaust intake space exhaust intake space exhaust. Remember there is a little time between the intake and exhaust stroke to allow the fuel to be pushed from the crankcase into the combustion area, so rhythm is the duration of the port window. And timeing this is on piston ported engines where the duration really matters. Thats why on dirt bikes they use reed valves. If you really mess up in the intake area you will have to make a reed cage, and thats not a bad thing if you was to make a reed cage and put reeds on your saw. But im not sure if you would be able to put the plastic parts back on anyways. The main thing to remember is when messing with the intake side of things improveing flow is a good thing. But watching the duration as well you got to have that moment where its closed to allow the pistons downward movement to push the air and fuel into the transfer ports into the combustion chamber. We wouldnt half to worry about this if we had a reed cage. If there are some people in the forum that can make some reed cages for chainsaws, I would buy one. The reed cage is awesome imo because as soon as that piston starts going down it closes and you get almost the entire downward pressure of the piston to pack all the air and fuel into the combustion area. Meaning you can open your intake as far as you like almost. Anyways, back to the piston ported engine, so when working on the intake side just remember there has to be some time in there to allow the piston to push the fuel and air into the transfers,and into the combustion area so just watch the rhythm of your engine and think of it like a song in your head the best i can decribe it is with a tune.

I tried,alot of capitalization and a whole lot of periods and commas.