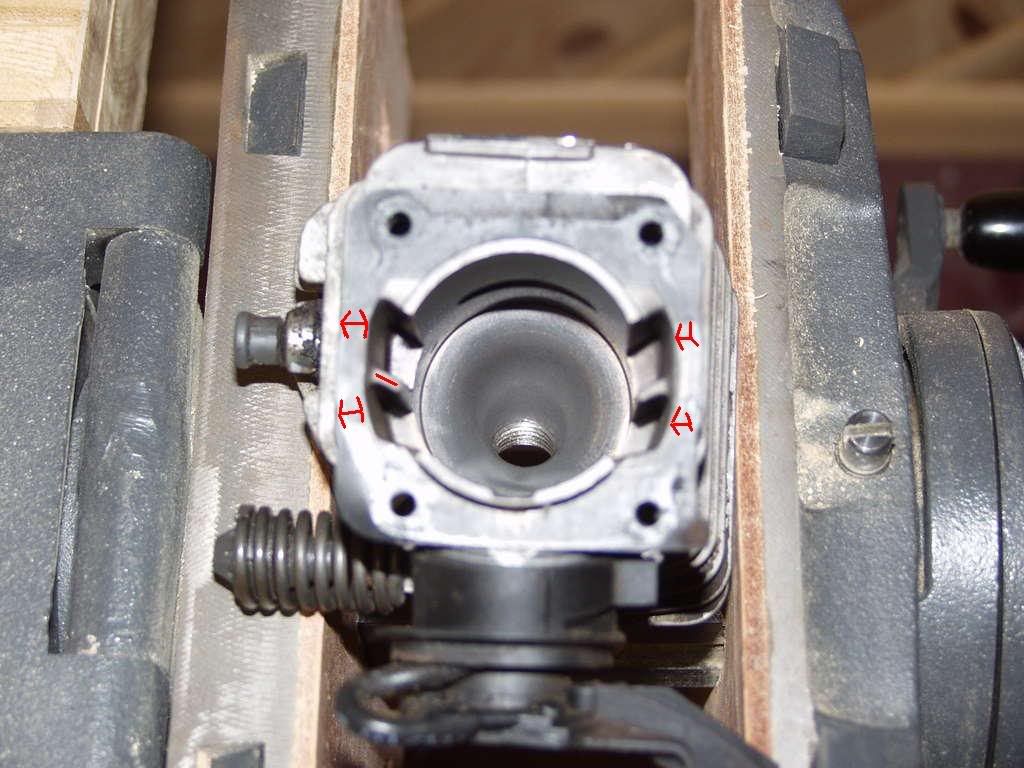

Several things I noticed here.

First you show raising the exhaust port. That is something I rarely do. This will cost you compression and torque. If you're after RPMs, you'll get them anyway with a good port job. I typically see about a 1500 RPM increase at WOT without raising the exhaust.

You show raising the intake as well. I'm not sure why you'd want to do this since the intake opens from the

bottom up. If you want to increase intake duration, you do it by lowering the port and widening.

Be careful enlarging the transfers. Yes, they may flow more volume, but at the expense of velocity.

I

always widen the ports; intake, exhaust, and transfers. If not, you're not really doing much of a port job. I shoot for intake and exhaust port widths of 70% of bore diameter. This is not always possible though. Sometimes you are limited by skirt width, ring end locations, etc. The transfers I widen and angle towards the intake. I usually raise them a couple of degrees as well, especially if I lowered the cylinder. If you're not comfortable messing with the transfers, then leave them alone. You'll see significant gains without changing them at all.

Port shape is

extremely critical. The top and bottom of the exhaust port are most critical. The rings travel completely over it with every stroke. They need to be concave, not even flat. When done with port shape it's

very important to put a bevel back on the top and bottom as well. This helps significantly in keeping the ring from snagging and destroying your work.