As quoted from Zenoah's website. BTW, Redmax uses Zenoah engines.

Zenoah is the first company in the world to achieve extremely low emission two-cycle engines. They have named this engine the Strato-Charged™ engine. 2-cycle engines have a simple structure, and are light and compact. However, due to their structure, about 30% of the mixture gas is not burned (unburned mixture gas) and is discharged as emission gas. There are various barriers that hamper the attainment of reduced emission for 2-cycle engines including a weight increase, larger engines and reduced ease of maintenance.

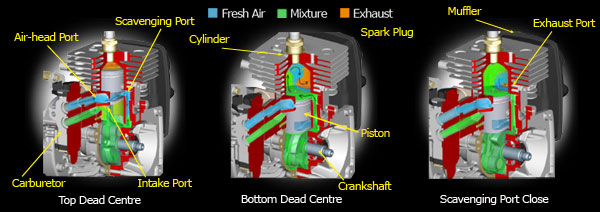

By employing a revolutionary engine air intake and scavenging system, this engine makes it possible to greatly reduce the unburned mixture gas. At the same time, it also has the effect of reducing emission gas to give cleaner exhaust.

Fresh air, which flows into the cylinder from the innovative air inlet port, expels the burnt gas so the mixture gas isn't depleted and is used effectively for the next combustion cycle. The newly designed combustion chamber and spark plug positioning ensure highly stable combustion without miss-firing and clean exhaust at 1/3 of the previous level. This new engine is named "Strato-charged™ engine" after the Zenoah original stratified scavenging engine without a catalytic converter.

Features of Innovative Zenoah StratoCharged™ engine are:

Low emission

Low fuel consumption

Low noise

Low exhaust gas odor and

High power comparing to our current models of the same displacement.

click on the link i posted

click on the link i posted